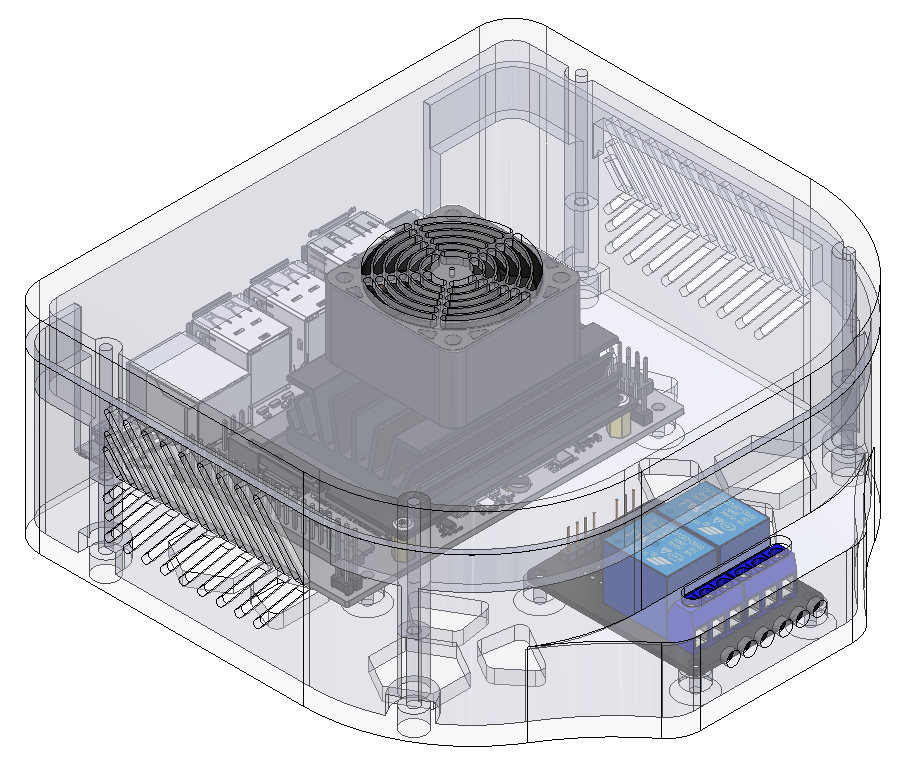

With extensive training and experience, we support product improvement processes. We incorporate computer-aided design tools with innovative product optimization solutions applied from the concept, modeling, assembly and testing phase to the supervision and inspection of mass production or assembly. We work hand in hand with our clients in changes, in the adaptation of existing products to the development of new products with the use of work methodologies and good practices, which allows us to offer efficient solutions, reducing development times and launching new products.

Design/modeling of products (parts)

Design/modeling of product assemblies (projects)

Organizational methodology of design work.

Preparation of digital engineering drawings.

Automation of design processes.

Preparation or installation manuals

Representation and animation of products.

Functional and kinematic analysis

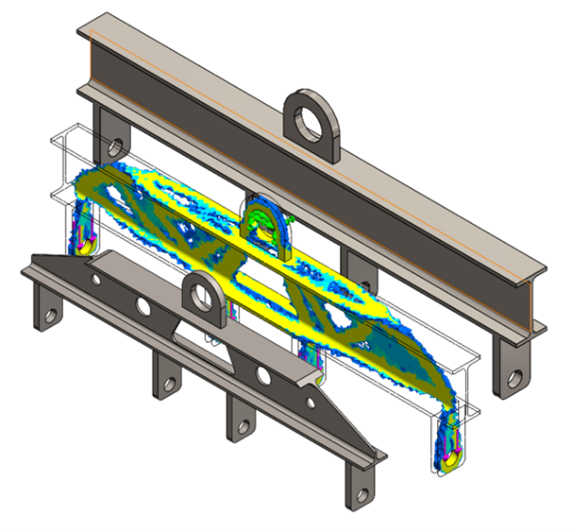

We have developed several projects in the fields of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). We have the capacity and technical experience to simulate its behavior according to its real conditions in order to optimize and adjust the design, minimizing possible failures during the expected life cycle. Shorter product launch times and the need to minimize the number of physical prototypes make design simulation a vital and highly effective tool throughout the product design and development process, resulting in a product with greater reliability, innovative and highly commercially competitive.

Static and dynamic analysis

Loads under linear and non-linear conditions

Analysis of plastic product injection process factors

Geometric and topological optimization of products

Static and transient calculations in fluid dynamics

Evaluation by thermal simulation of products

Linear and nonlinear buckling analysis

Fatigue resistance and service life

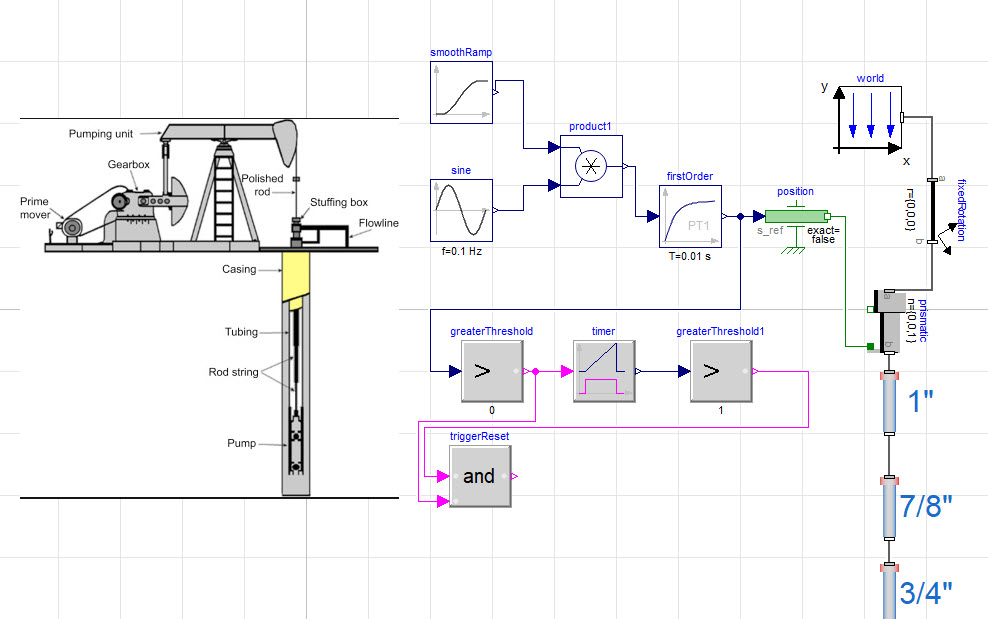

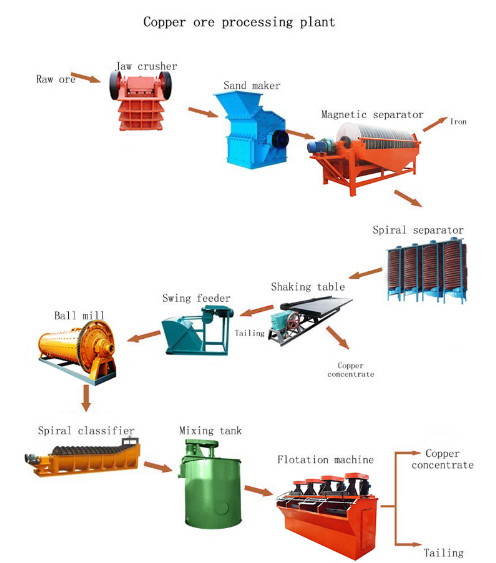

We are the DymoLATAM GROUP, we specialize in developments based on Modelica-Dymola, with the aim of process simulation, reducing development times and creating innovation in the industry. Additionally, we focus on CO-SIMULATION between process analysis and finite element calculations with Abaqus. We work together with the Universidad Tecnologica Nacional – Facultad Regional Buenos Aires – Argentina with the researcher, doctor and engineer Claudio Jouglard.

Simulation and optimization of mining processes such as flotation in the copper extraction process.

Libraries for the simulation and control of process plants. For example, application plants in the pharmaceutical industry.

Simulation of energy generation systems such as wind and solar plants.

Developments oriented to the calculation and prediction of the life of components such as Sucker-Rod, Tubing and Casing.

Focusing on digital transformation, we are executing and implementing successful document management (PDM) and project management (PMI-SCRUM) methodologies, consolidating our experience and extensive knowledge of innovation in the industry. We deliver our projects on time according to the established schedules, thus avoiding cost overruns and delays for our clients. Our quality is also compliance. With extensive training and experience, we support product improvement processes.

We incorporate computer-aided design tools with innovative product optimization solutions applied from the concept, modeling, assembly and testing phase to the supervision and inspection of mass production or assembly.

We work hand in hand with our clients in changes, in the adaptation of existing products to the development of new products with the use of work methodologies and good practices, which allows us to offer efficient solutions, reducing development times and launching new products.

Evaluation and integration of the data management system (PDM).

Evaluation and integration of project management systems (PDM – Management).

Data migration and integration with SAP, ERP and CRM systems among others

Integration and collaboration of CAD data with other digital systems.

Creation of workflows and work structures.